We design and manufacture large-scale 3D printers.

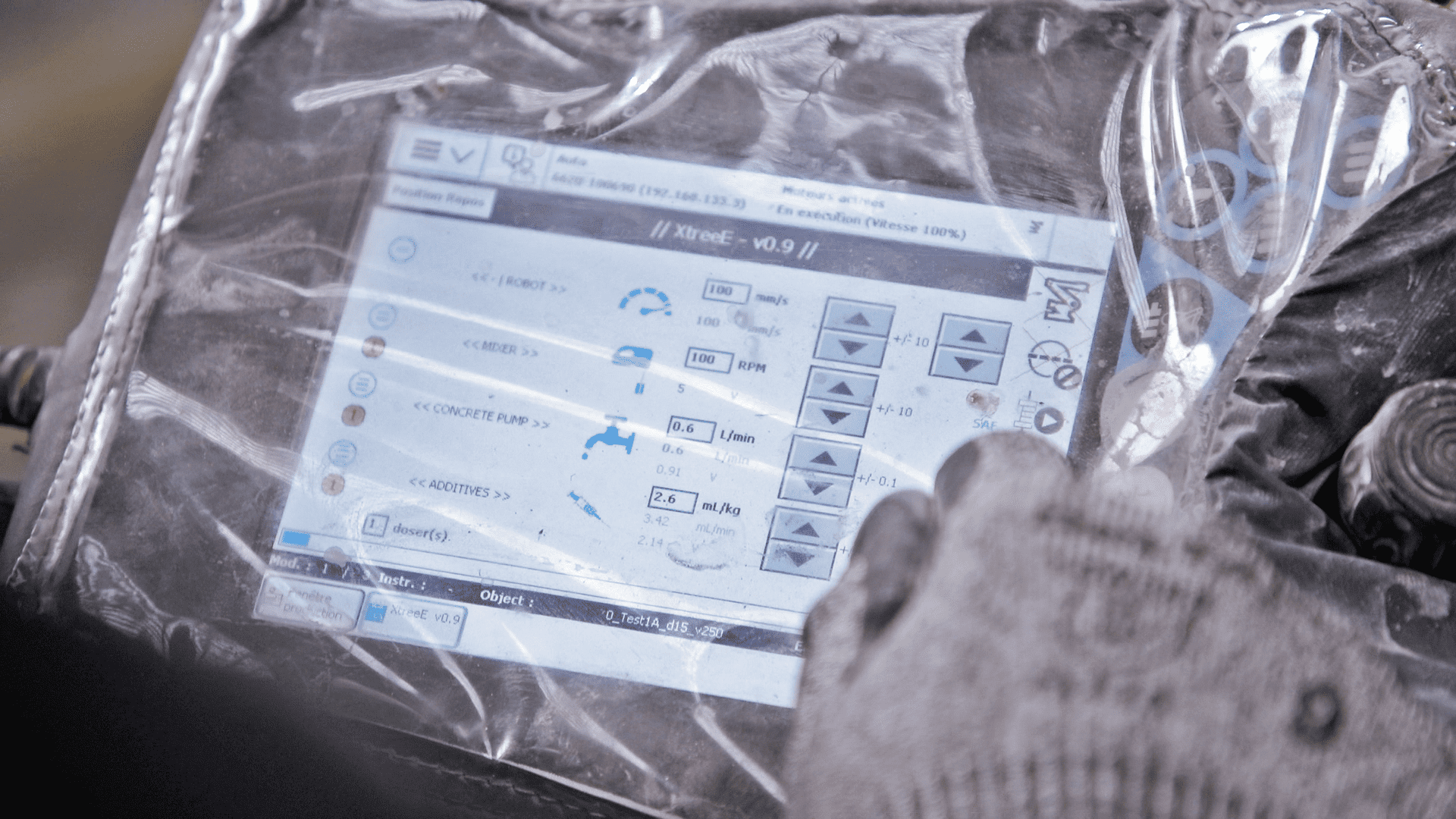

XtreeE printing system is a production-oriented system, which consists in a large-scale, fully integrated and certified printing cell, including an automatic Concrete Preparation Unit (CPU). Supervision covers the whole printing process, from dosing to extrusion.

Reliable quality

The printing head doses concrete and admixture, mixes them precisely and extrudes controlled layers of concrete. XtreeE bi-component technology enables to enhance quality by adjusting the material locally to the geometry to be printed

Multiple materials

XtreeE bi-component systems can extrude a variety of materials.

It is indeed one of the purposes of our operating partners : to develop new printable materials, and especially locally sourced ones.

Today, among the developed materials at XtreeE are various mortars (including white mortar), earth-based materials, plaster and geopolymers.

Limitless design

The system relies on three software solutions, to manage printing toolpath and supervision :

Adjuventation, orientation, etc

Real-time process monitoring

The whole printing system is embedded with sensors. All this data is gathered into one web interface, allowing control, supervision and data logging for further analysis. Basic data includes:

Concrete feeding pressure, Concrete dosing pressure, Concrete dosing pump speed, Concrete dosing pump torque, Head mixer speed, Head mixer torque

Additional measurement features are constantly developed at XtreeE and can be adapted to specific needs.

Data feedback

All data is stored at XtreeE platform, allowing the user to precisely check and analyse printed elements.